Dec 2021 – SKET has had a good delivery year

This year, SKET Verseilmaschinenbau delivered 15 machines, orders from different industries and from different markets around the world. Among others […]

Apr 2021 – Customized refurbishment and upgrade of stranding machines

Solid stranding machines are characterized by a very long service life despite permanent and rough use in the steel rope […]

Nov 2020 – SKET delivers a fast double twist stranding machine for the production of ropes

In December 2020, SKET will deliver a new double twist stranding machine of the type MSDN 630 / 7xOD315 (B60) […]

Participation in wire Düsseldorf 2020 canceled

Dear customers and business partners, Due to the renewed increase in the number of infections and the associated travel restrictions, […]

Sep 2020 – SKET delivers a large high-speed tubular strander with a bull head

In September 2020, SKET will deliver a large high-speed tubular stranding machine with a bull head type SRW 12×800 + […]

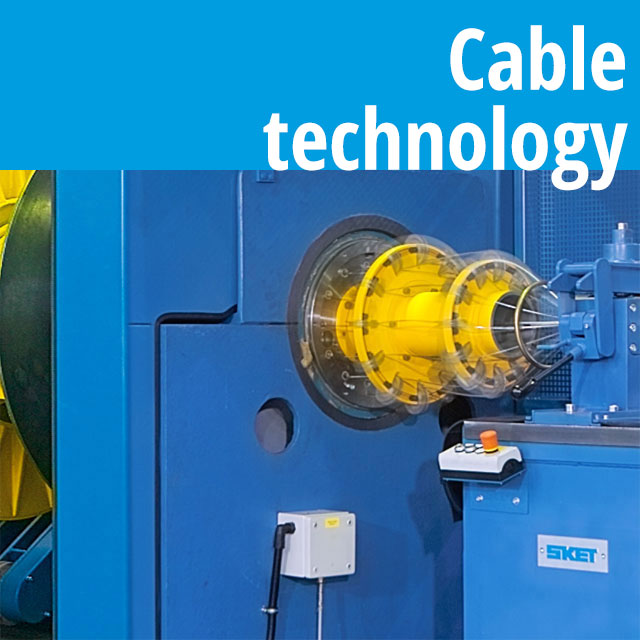

May 2020 – Take a look at our highspeed tubular strander

Please take a look at testrun of one of our technologically advanced machines in our workshop in Magdeburg. The shown […]

Apr 2020 – SKET delivers a large high-speed tubular strander to Russia

SKET- delivers a large high-speed tubular strander SRW 36×630 to Russia, at the end of March 2020, despite ongoing challenges […]

Aug 2018 – Successful Handover to Hengtong Submarine Power Cable Co., Ltd of SKET machinery

After successful installation and commissioning of a Vertical Stranding Line and an Armoring line, the final acceptance was signed by Manager Mr. Qian Zhikang and Production Manager Mr. Pan Wenlin after qualified production of 27km High Voltage Offshore Power Cable (220kV, 3×500 mm², XLPE insulated).

Dec 2015 – SKET- Cage Type Stranding Machines fully and successfully in operation

The large, heavy duty cage-type stranding machines supplied by SKET Verseilmaschinenbau GmbH in recent times for the manufacture of special […]

Nov 2015 – SKET supplies German wire rope manufacturers with double twist bunching technology

During recent weeks, SKET Verseilmaschinenbau Gmbh has supplied two leading German wire rope manufacturers with double twist bunching machines. One […]

Oct 2015 – Another large order is placed with SKET

Last month saw the successful conclusion of a large contract for stranding machinery for the production of steel wire rope […]

Sep 2015 – Our fairs participation during Autumn, 2015

During the first half of 2015 SKET Verseilmaschinenbau Gmbh has already taken part successfully in a number of exhibitions in […]

Aug 2015 – Production continues at full stretch in spite of the holiday season peak

As we all know, the summer months of July and August are the “holiday months” in Germany. And it is […]

Jul 2015 – Chinese cable manufacturer orders stranding machinery

Photo: An MKD 630 tandem cage-type stranding machine during assembly at SKET A long time Chinese customer of SKET Verseilmaschinenbau […]

Jun 2015 – Our trade fair participation, in Istanbul in March and in Atlanta in April

In recent years the development of our company’s relations with Turkish wire rope manufacturers has been extremely positive. We have […]

May 2015 – Switzerland is famous not only for its banking system and its delicious chocolate …

Everybody is talking about Switzerland, not only because of its banking system and its Alpine milk chocolate. Machinery and equipment […]

Apr 2015 – SKET supplies one of the largest manufacturers of steel wire rope in Eastern Europe with the most up-to-date stranding technology for the production of elevator ropes

Last year, one of the largest producers of steel wire rope in Eastern Europe ordered stranding machine technology from SKET […]

Mar 2015 – FIRST CLASS STRAND manufactured on SKET Drum Twisters

Our Company’s product range embraces a wide range of machines and equipment for the manufacture of electric cable and steel […]

Feb 2015 – SKET receives another large order from Turkey

In recent years the company has been pleased to be able to regularly record a number of orders from Turkey. […]

Jan 2015 – SKET Central Strander – the “Renner” in cable production – another order from a long standing customer

There are two meanings which can be applied to the German word “Renner” in relation to the Central Strander. On […]